ASME B16 5 Long Weld Neck Flange Manufacturer

We are ASME B16.5 Long Weld Neck Flange Manufacturer, Supplier, and Exporter in India — Shribhairav Forge is a trusted manufacturer and exporter of ASME B16.5 Long Weld Neck Flanges, offering high-quality products built for durability, precision, and performance. Our Long Weld Neck (LWN) Flanges are designed for critical applications where high pressure, high temperature, and cyclic loading conditions exist.

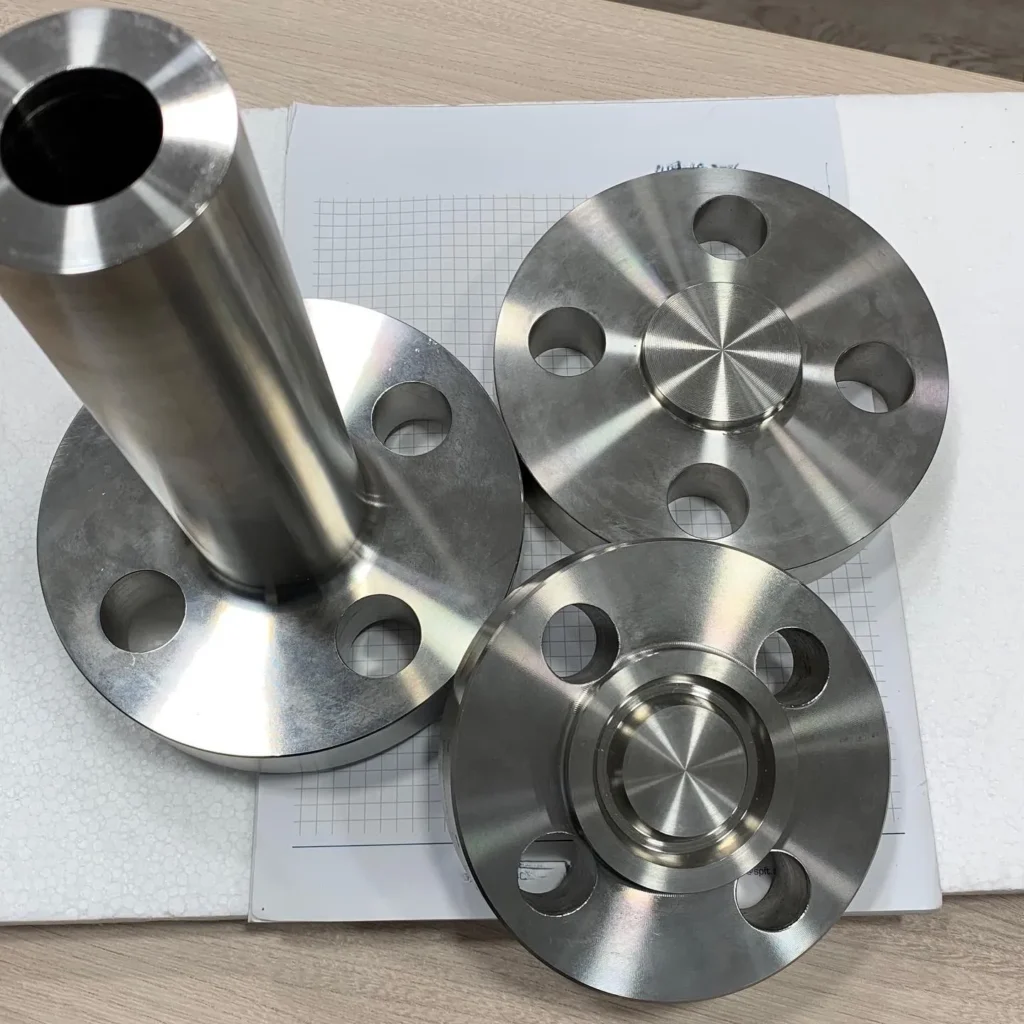

What are Long Weld Neck Flange?

Long Weld Neck (LWN) flanges are a unique variety of flange characterized by an extended neck that gradually narrows to align with the wall thickness of a pipe or vessel. This extended neck offers additional support and facilitates a seamless transition of stress between the flange and the attached pipe, rendering them suitable for high-pressure, high-temperature, or critical service applications. They are predominantly utilized in process plants, refineries, and power generation systems.

The key characteristic of a Long Weld Neck flange is its extended hub or neck, which functions as an integrated nozzle. In contrast to standard weld neck flanges, the LWN flange can be welded directly to a vessel or pipe without requiring an additional pipe extension. This design enhances structural integrity, decreases turbulence, and lowers the likelihood of leakage. They are generally offered in a range of pressure ratings and materials, including carbon steel, stainless steel, and alloy steel, based on the specific application needs.

Long Weld Neck flanges are primarily used in pressure vessels, heat exchangers, and storage tanks where high stress and frequent temperature variations occur. Their robust construction ensures excellent resistance to bending, vibration, and corrosion. By maintaining proper alignment and providing a strong, leak-proof connection, LWN flanges enhance the safety and efficiency of piping systems in demanding industrial environments.

Standard Specifications for Long Weld Neck Flange

Supplier Of BS10 Table E Weld Neck flange, Weld Neck Flange Schedule 10, Weld Neck Flange Flat Face Dimensions, Weld Neck Flange Raised Face Dimensions,Weld Neck Flange Suppliers UK

Dimensions: ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Size Range: 1/2" (15 NB) to 48" (1200NB)

Pressure Classes: 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS, DIN Standard ND-6,10, 16, 25, 40 Etc.

DIN Standards: DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN 2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636,DIN2637, DIN2638, DIN2673

BS Standards: BS4504 , BS4504, BS1560, BS10

Flange Face Types: Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

We provide Value Services like CNC Machining and Customised Flanges.

Material & Grades of Weld Neck Flanges (WNRF) :

ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L

Duplex & Super Duplex Steel Weld Neck Flanges : ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

Low Temperature Carbon Steel Weld Neck Flanges : ASTM A350, LF2, LF3

Alloy Steel Weld Neck Flanges : ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

Copper Alloy Steel Weld Neck Flanges : ASTM SB 61 , SB62 , SB151 , SB152 UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200

Nickel Alloy Weld Neck Flanges : ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020)

ASME B16.5 Raised Faced Weld Neck Flanges Available Types

| Weld Neck Raised Face Flange | Raised Faced Weld Neck Flanges |

|---|---|

| Weld Neck Plate Flanges Dealer | ASME B16.47 Series A and B WNRF Flanges Exporter |

| Titanium ASME B16.47 Series A and B WNRF Flanges | Inconel Weld Neck Flanges |

| Super Duplex Steel Weld Neck Forged Flange | Copper Nickel Weld Neck Pipe Flanges |

| Stainless Steel Weld Neck Flanges Suppliers | SS Weld Neck Flange |

| High Nickel Alloy WNRF Flanges | Hastelloy Flat Faced Weld Neck Flanges Stockist |

| Carbon Steel Weld Neck Flange | High Quality WNRF Flanges Manufacturer |

| ASTM A182 Stainless Steel WNRF Flange | Duplex Steel Weld Neck Flange |

| ASME B16.5 WNRF Flanges | ANSI B16.5 Class 150 Weld Neck Flanges |

| ANSI B16.5 Weld Neck Flanges | Weld Neck Flange Dimensions |

| ANSI B16.5 class 150 WNRF Flange Stockholder | ANSI 150 Weld Neck Flange Distributors |

ASME B16.5 Weld Neck Flanges Application

ASME B16.5 Weld Neck Flanges are known to deliver exceptional performance and are generally developed for meeting the demands. We offer a broad range of Flat Faced Weld Neck Flanges through a worldwide network of stock-keeping branches. These Weld Neck Flange is use in various industries like :

- Stainless Steel Weld Neck Flanges uses in Oil and Gas Pipeline

- Weld Neck Raised Face Flanges uses in Chemical Industry

- Alloy Steel WNRF Flanges uses in Plumbing

- Flat Faced Weld Neck Flanges uses in Heating

- Weld Neck Pipe Flanges uses in Water Supply Systems

- ANSI B16.5 Weld Neck Forged Flanges uses in Power Plant

- Weld Neck Flange uses in Food Processing Industry

- Weld Neck Flanges uses in Structural Pipe

FAQs

How do you ensure consistent service quality?

We maintain consistent service quality by implementing rigorous training programs, regularly updating our processes, and gathering feedback from customers. This allows us to continuously improve and adapt to their needs, ensuring high standards are met at every touchpoint.

What key factors create memorable customer experiences?

Memorable customer experiences are created by understanding customer needs, providing personalized interactions, ensuring prompt responses, and maintaining a positive, friendly attitude. Consistency in service quality and exceeding expectations are also essential for lasting impressions.

How do you handle customer issues efficiently?

We handle customer issues efficiently by actively listening, identifying the root cause, and offering timely solutions. Clear communication and regular updates keep customers informed, while swift action and follow-up ensure a positive resolution.

What sets your service apart from competitors?

Our service stands out through personalized attention, quick response times, and a commitment to continuous improvement. We prioritize customer satisfaction, consistently adapting to feedback and industry trends to deliver exceptional, tailored experiences.

Forged for Perfection.

Trusted for Precision.

Delivered with Confidence.

Products

Materials

Contact

- sales@shribhairavforge.com

- +91 9969566209

- +91 22 6636 2333

- Plot 59, Dr M.G Marg, Mumbai - 400004, Maharashtra, India

- Shribhairav Metal Corporation